1

Machine demonstration

At the start of a turnkey project customers are invited to view our range of machines. During the visit customers can meet our application team to discuss the scope of the project and see a live demonstration of the Star machines.

2

Machine is prepared

The star* application team recommends the ideal machine which corresponds to the scope of the project. We prepare the machine in our workshop so that the turnkey project can start.

3

Programming

The star* application team checks all the drawings including the geometrical tolerances, selects the right machining strategy and starts with the programming using our software system.

4

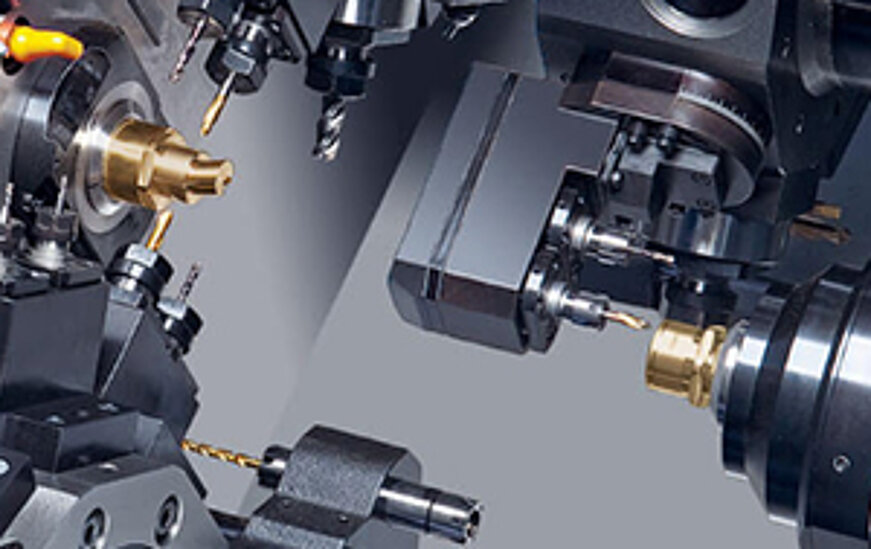

Tool selection

Depending on material, complexity of the part or customer requirements, our application team selects a suitable tool from one of our suppliers. This ensures that the ideal cutting rate is achieved with a consistent service life.

5

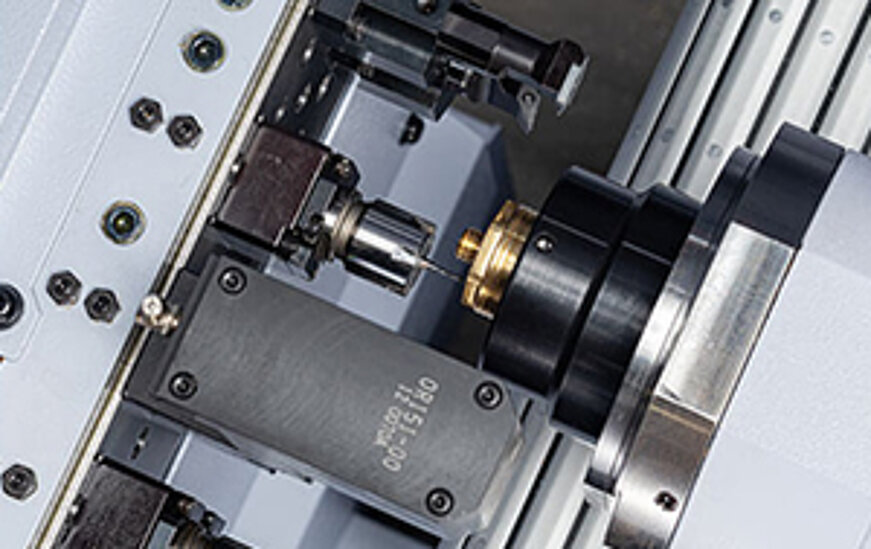

Manufacture and inspection of the part

After the part has been programmed and a tool selected, a sample of the part is manufactured and sent to the customer for inspection.

6

Process development

When the part remains unchanged and the required quality has been achieved, our application team starts to refine the program to minimise the cycle time and simultaneously maintain the process stability.

7

Project handover

In this phase the customer is invited to visit our headquarters to inspect the machining process and check the quality, cycle time and tool configuration.

8

Accepted parts

As soon as the customer is satisfied with the parts, he is asked to formally accept the parts and sign to confirm that the project is complete.

9

Increase profits

After the successful installation of the machine, customers will be able to increase profits through the precise and efficient manufacture of high-value parts.