![[Translate to English:] Kinematik der ST-38](/fileadmin/_processed_/3/b/csm_star_st38_kinematik_4dbd340640.png)

ST-38

| Diameter | 38 mm / 42 mm (option) |

|---|---|

| Headstock stroke | 350 mm |

| Machining possibilities |  |

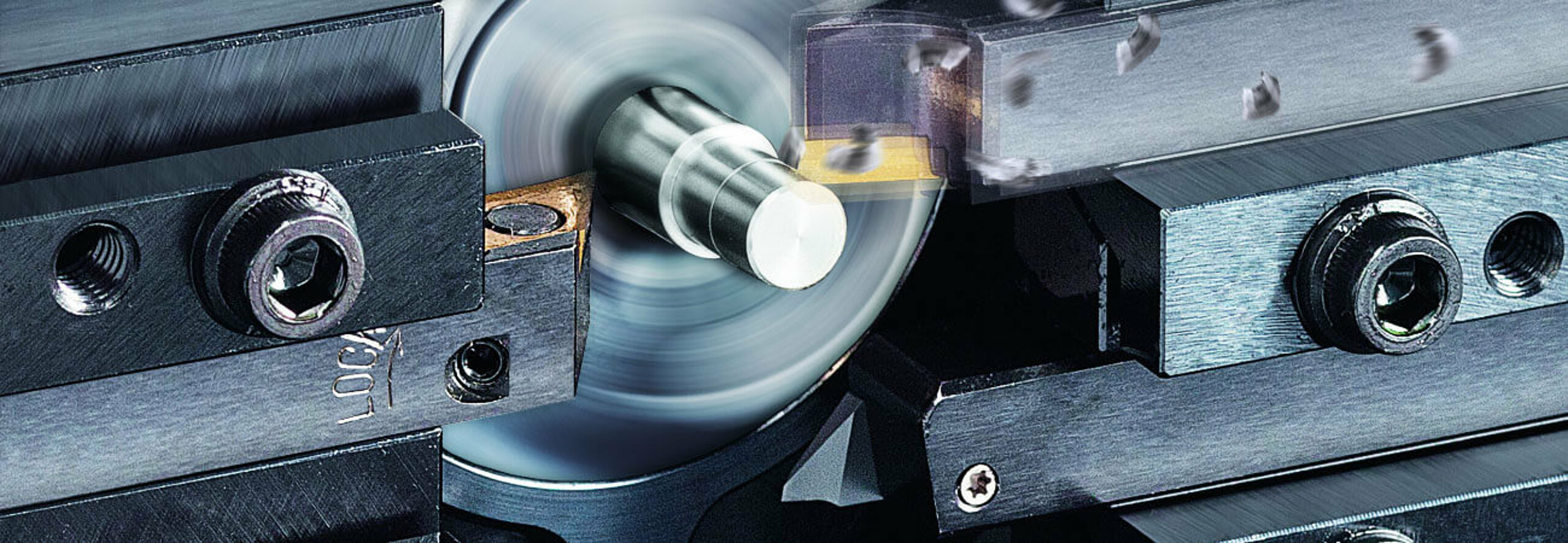

Kinematics & tools

- 30 + α tools for main and backworking on 3 turrets

- 12 axes

ST

38

POWER, SPEED

AND PERFORMANCE!

The ST-38 from STAR Micronics further develops the series of the complex KNC-32 and SV-32 machines.

A machine for highly complex parts, yet easy to program in the usual way with the FANUC control system with machining possibilities for parts up to a workpiece diameter of 38 mm.

The 3 turrets allow for almost limitless machining flexibility. The ST-38 therefore enables the machining of turned parts which require up to 60 tools.

![[Translate to English:] ST-38](/fileadmin/_processed_/c/3/csm_star_st38_vorteile_57e9e0f815.png)

Advantages

- FANUC 31i-B5 control system with handle

- C axis control as standard on main and sub spindle

- fully independent backworking with 10 stations

- movable control panel

- two turrets for simultaneous machining on the front side

- additional longitudinal axis on tool post 3

- three fully independent tool systems

- turret drive power 4 kW

Specifications

| General information | ST-38 |

|---|---|

| Number of axes | 12 |

| Max. rapid traverse speed | 30 m/min |

| Weight | approx. 6,250 kg |

| Coolant tank capacity | 245 litres |

| Dimensions (L x W x H) | approx. 3,477 x 1,859 x 1,865 mm |

| Main spindle side | ST-38 |

|---|---|

| Number of axes | 7 |

| Axes main spindle (headstock) | Z1 / C1 |

| Axes turret 1 | X1 / Y1 |

| Axes turret 3 | X3 / Y3 / Z3 |

| Max. machining diameter | 38 mm / 40 mm (option) |

| Max. headstock stroke | 350 mm |

| Max. main spindle drive power | 11 kW |

| Max. main spindle speed | 7.000 1/min |

| Tools on the turret | |

| No. of tool stations per turret | 10 tools (10 power-driven) |

| Max. turret drive power 1 and 3 | 4.0 kW |

| Max. turret speed 1 and 3 | 5,700 rpm |

| Sub spindle side | ST-38 |

|---|---|

| Number of axes | 5 |

| Axes sub spindle | Z2 / C2 / YA2 |

| Axes turret 2 | X2 / Y2 |

| Max. chucking diameter | 40 mm |

| Max. sub spindle drive power | 7.5 kW |

| Max. sub spindle speed | 7,000 rpm |

| Backworking tools | |

| Tool stations | 10 tools (10 power-driven) |

| Max. turret 2 drive power | 4.0 kW |

| Max. turret 2 speed | 5,750 rpm |

Standard scope of delivery

- CNC control FANUC series 31i-B5 control with handle

- 10 + α tools for turning, drilling, cross machining on 3 turret

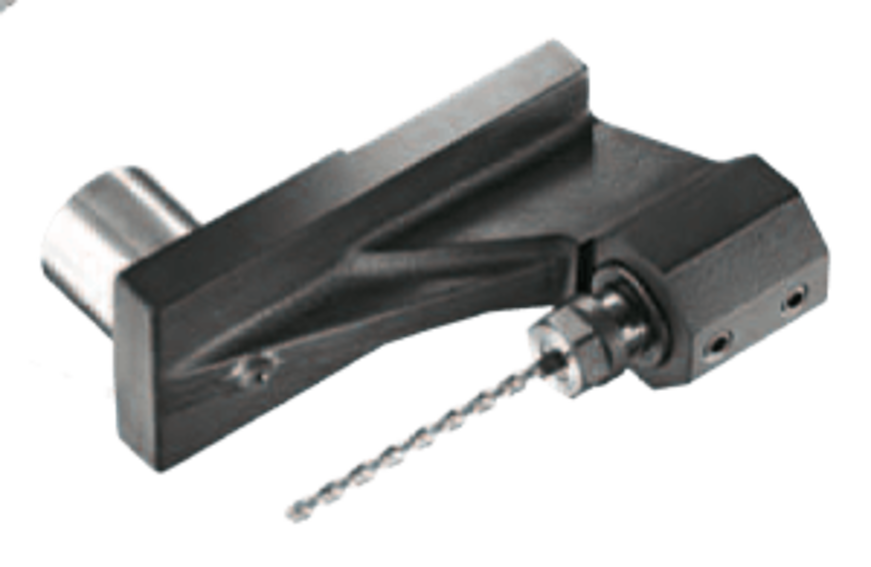

- broken cut-off tool detector

- parts ejection detector

- sub spindle for backworking

- sub spindle air blow unit

- parts receptacle

- pneumatic unit with maintenance unit

- parts ejection detector for the sub spindle

- parts conveyor to remove the parts

- oil lubrication system

- separate coolant tank with level monitoring and coolant flow detector

- bar feeder interface

- levelling pads and adjustment screws

- worklight

- toolbox with special tools

- metric input

- tool nose radius compensation

- constant cutting speed for main and sub spindle

- multiple canned cycles

- operating hours display

- parts counter

- automatic power supply cut-off function

- interfaces to input and read data

- program sequence controllable with handle

- cylindrical interpolation

- polar coordinate interpolation

- polygon machining

- helical interpolation

- 3D coordinate conversion mode

- bar feeding: bar feeder

- chip disposal: chip conveyor

- long parts ejector

- beacon: acc. to customer requirements

- high pressure unit: 50 to 300 bar

- fire protection: small fire extinguishing system

- complete filtration coolant

- Tools in the internet at www.star-tools.eu

Machining examples

Selection from our

range of tools

Your advantages

with star Micronics

- Training

STAR Micronics GmbH offers special training sessions for machine operators. You as customer can decide whether to have the training in our company or on your premises. The training is naturally exclusively for your personnel and specifically designed for your range of parts. - High pressure unit

The machine can be retrofitted with high pressure units from 50 to 300 bar. In addition, other developments are available to you, such as programmable pressure control or complete filtration. - Cooling lubricants

The machine can be run with oil or with aqueous emulsions. However, we recommend the use of oil as this is far more beneficial to the longevity of the machine. - Bar feeder

All commonly available bar feeders (FMB/IEMCA/LNS) can be used with the machine. The software interface is included in the machine as standard.

- Chip conveyor

The machine can be fitted with a chip conveyor or a chip flushing system. - Peripherals

Peripheral components such as parts separators, purchased coolant units (oil/emulsion), coolant filters, fire protection systems and TPM (tool process monitoring) can also be offered. A retrofit of peripheral components is always possible. - Service

SSC star* Service Connect as 24/7 customer portal and online connectivity for your machines, tickets and service calls. A current overview can be called up at any time. In addition, you have access to the star* knowledge database

Müller Products can easily be combined with and configured to your star* machine.

REQUEST quotation NOW

You will receive a quotation for a star* ST-38 with a standard configuration.

Download

ST-38 brochure

HFT Flyer

![[Translate to English:] ST-38](/fileadmin/_processed_/d/2/csm_star_st38_838722024d.png)

![<strong> Cross drilling and cross milling. </strong><br>

Simultaneous and independent overlapped cross machining.

[Translate to English:] Querbohren und Querfräsen](/fileadmin/user_upload/img/produkte/st38/star_st38_1_querbohren.jpg)

![<strong> Cross machining and off-centre drilling </strong><br>

Simultaneous cross and front machining.

[Translate to English:] Querbearbeitung und außer mittiges Bohren](/fileadmin/user_upload/img/produkte/st38/star_st38_2_querbearbeitung.jpg)

![<strong> Turning and drilling </strong><br>

Simultaneous turning and drilling with independent feeds.

[Translate to English:] Drehen und Bohren](/fileadmin/user_upload/img/produkte/st38/star_st38_3_drehen.jpg)

![<strong> External thread whirling </strong><br>

External thread whirling on the main and sub spindle.

[Translate to English:] Außengewindewirbeln](/fileadmin/user_upload/img/produkte/st38/star_st38_4_aussengewinde.jpg)

![<strong> Skewed cross machining </strong><br>

Angle-adjustable tool holders are available for machining on the main and rear side (0-180°).

[Translate to English:] "Schräge" Querbearbeitung](/fileadmin/user_upload/img/produkte/st38/star_st38_5_schraege.jpg)

![<strong> Overlapped machining on the main and sub spindle </strong> [Translate to English:] Zeitverdeckte Bearbeitung an Haupt- und Gegenspindel](/fileadmin/user_upload/img/produkte/st38/star_st38_6_zeit.jpg)

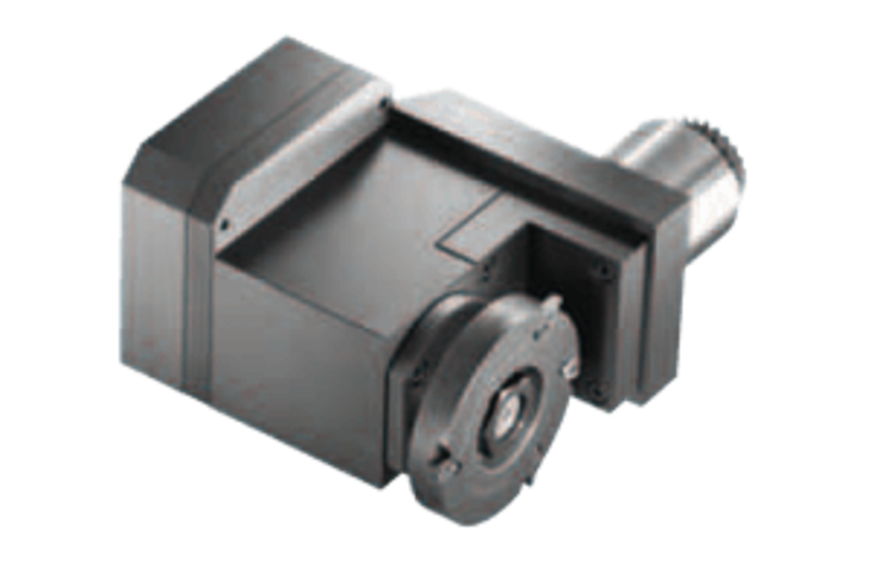

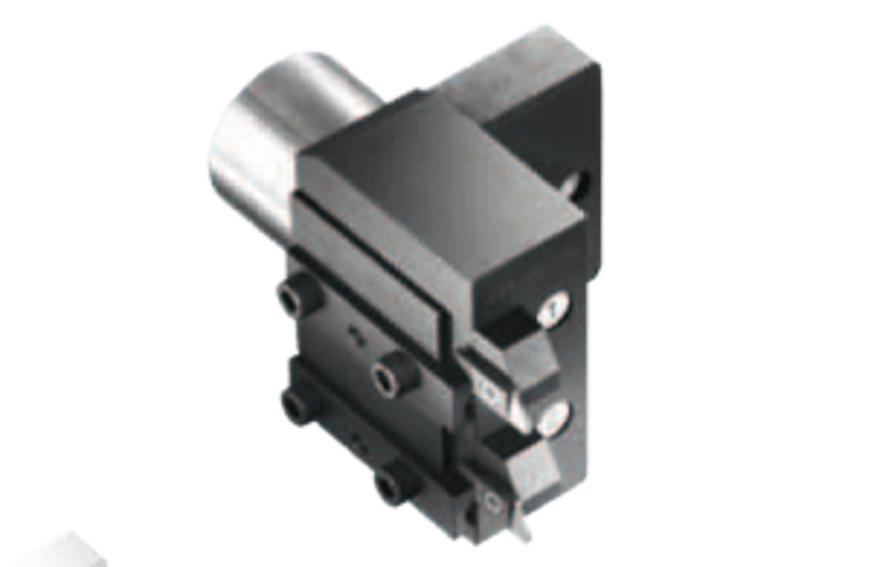

![[Translate to English:] 781-01](/fileadmin/_processed_/0/5/csm_star_781_01_1500d845ed.png)

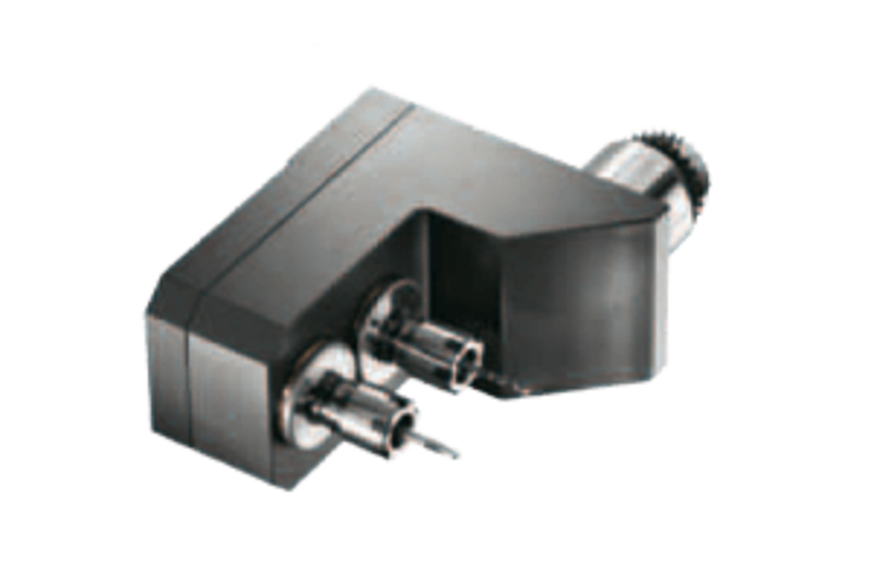

![[Translate to English:] 781-11](/fileadmin/_processed_/9/a/csm_star_781_11_58259a8e60.png)

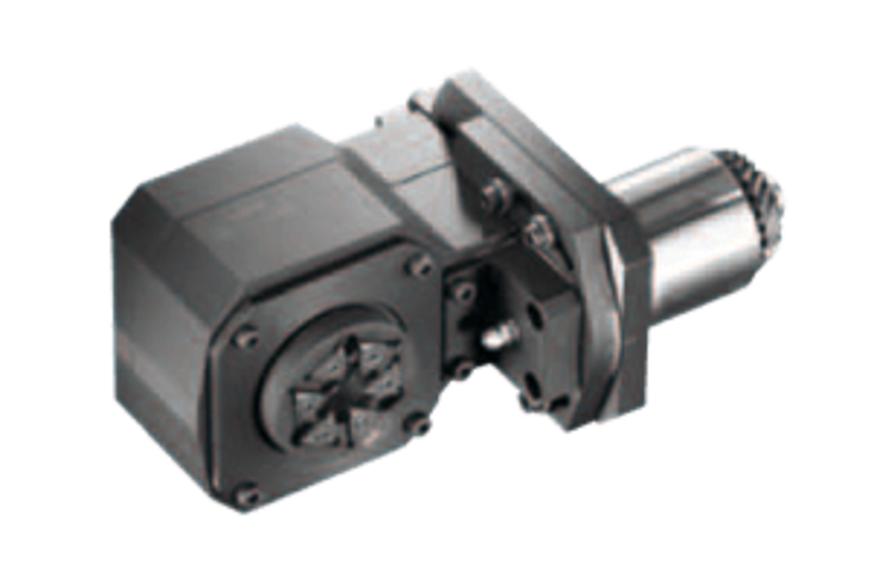

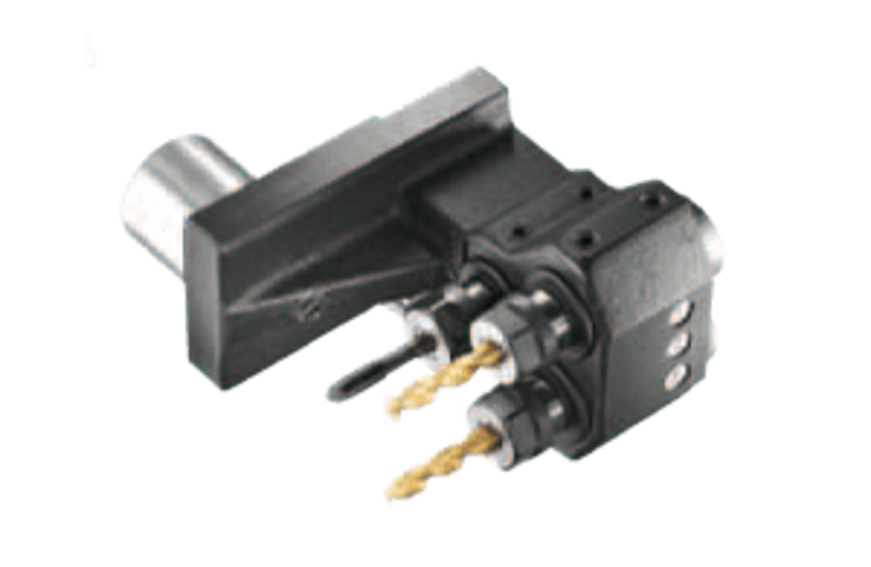

![[Translate to English:] 431-58](/fileadmin/_processed_/1/2/csm_star_431_58_f7000b574e.png)

![[Translate to English:] 431-63](/fileadmin/_processed_/a/d/csm_star_431_63_bef6198911.png)

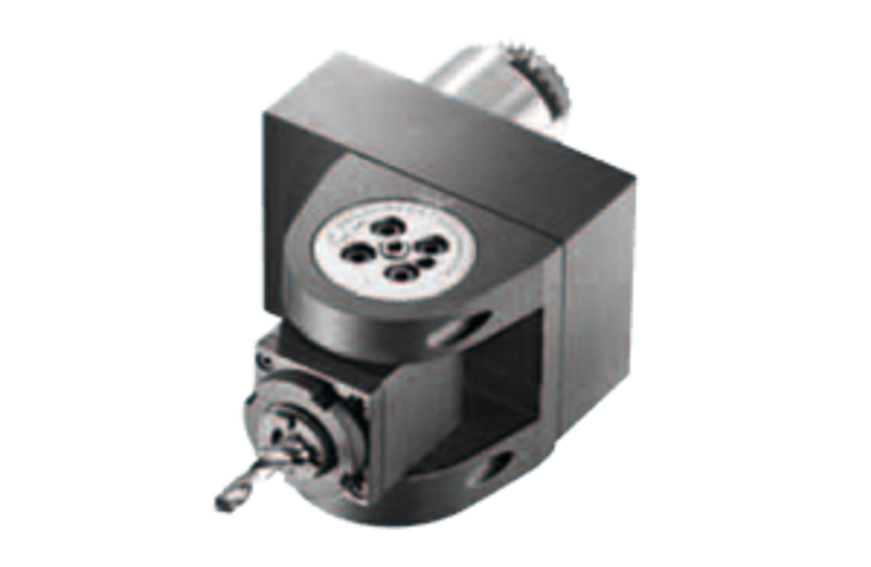

![[Translate to English:] 201-50](/fileadmin/_processed_/c/0/csm_star_201_50_8c56264a19.png)

![[Translate to English:] 581-51](/fileadmin/_processed_/c/0/csm_star_581_51_4bc27f6c39.png)

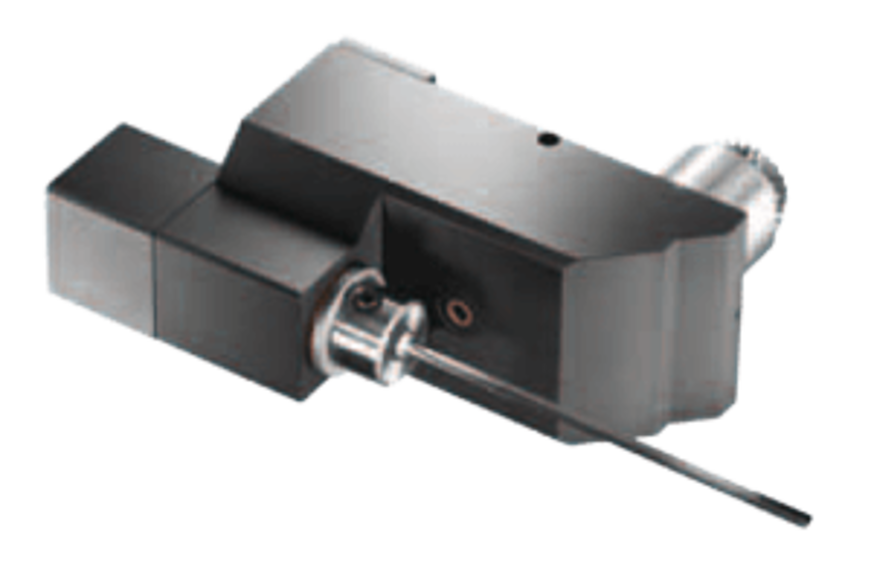

![[Translate to English:] 201-52](/fileadmin/_processed_/0/d/csm_star_201_52_54b727fe5f.png)

![[Translate to English:] 431-54](/fileadmin/_processed_/8/a/csm_star_431_54_6e74daf99e.png)